16

Factors influencing the yield and the quality of hemp (Cannabis sativa L.) essential oil

Christoph Meier and Vito Mediavilla

Swiss Federal Research Station for Agroecology and Agriculture

(FAL), Reckenholzstrasse 191, 8046 Zurich,

Switzerland e-mail: ch_meier@hotmail.com

Website: http://www.inaro.de

Meier, Christoph and Vito

Mediavilla 1998 Factors influencing the yield and the quality of hemp (Cannabis

sativa L.) essential oil. Journal of the International Hemp

Association 5(1): 16-20. The aim of this work was to assess the factors

influencing the yield and the quality of hemp essential oil. Several strains

were used to carry out field and greenhouse experiments, and as specimens for

scent tests and chemical analysis of the distilled oils.

Yields of oil were highest at seeding

rates of 5 kg/ha and when about a 50% of the crop had reached maturity.

Pollination led to significantly lower yields, but is not easy to prevent in the

field. Chemical composition showed almost no relationship to harvest dates or to

scores on the scent tests. The best scent quality was always obtained from

plants harvested one to three weeks before seed maturity (75% of seed matured).

The interval during which both yield and quality were high was rather short and

had to be assessed for each strain. The influence of other factors such as

weather and harvest technique were also evaluated.

Introduction

Essential oil is one of

the many products people may obtain from hemp (Cannabis sativa L.). It

contains many volatile compounds, mainly monoterpenes, sesquiterpenes, and other

terpenoid-like compounds (Turner et al. 1980) which can be isolated by

steam distillation. These volatile compounds can be used for cosmetics, as an

additive to food, in aroma therapy and in the future it may be of interest to

the perfume industry. It is also reported to have some pest-controlling

properties against bacteria (Fournier et al. 1978, McPartland 1997),

insects (McPartland 1997) and probably even against other plants (Pate 1994,

McPartland 1997).

Manufacture of essential oils from

hemp is presently rather rare. It is currently no more than a niche product

whose sales potential is unclear. In Switzerland, some farmers have produced

essential hemp oils since 1995. They are interested in the agronomic factors

influencing its yield and quality.

Mediavilla and Steinemann (1997)

studied the influence of the strain type on essential oil production. As known

for other plants, harvest time may have important consequences to essential oil

production (Husain 1994). In addition, plant density and even pollination may

influence inflorescence yield and thus essential oil yield.

Material and Methods

To assess the influence of

harvest time, sowing density and pollination, field and greenhouse experiments

were carried out.

Field experiments-

Plots were sown on the 17th of April

1997 in Tenniken (Switzerland) near Basle (Alt. 604 m; 7°50' E, 47°30' N) on

brown soil, fertilized with 120 kg/ha N.

Harvest time experiment-

Four strains (Table 1) sown at a

density of 30 kg/ha were harvested on several dates between August 4 and October

14, 1997. The developmental stage of the plants was determined at every harvest.

In biological terms, the plants were harvested between the beginning of female

flowering and senescence. The upper 50 cm of the inflorescences and leaves were

used to distill essential oil, as described below. Plant material was either

used fresh or kept frozen at -20°C until distillation.

|

|

|

|

|

| Futura | monoecious | France | X | X | |

| Fédora | monoecious | France | X | ||

| Félina 34 | monoecious | France | X | ||

| Kompolti | dioecious | Hungary | X | X | |

| Secuieni 1 | dioecious | Rumania | X | ||

| Swissmix | dioecious | Switzerland | X |

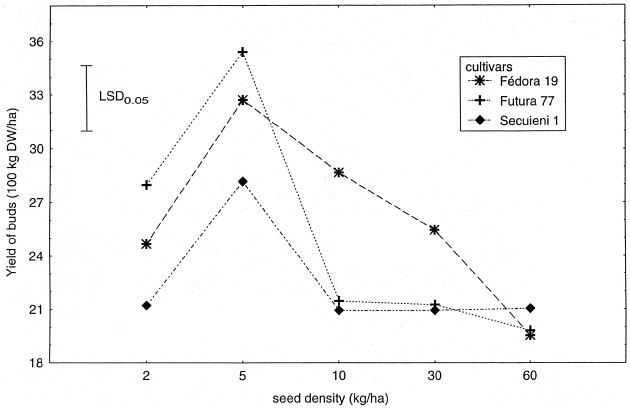

Seed density experiment-

Three strains (Table 1) were sown in

randomized plots with four replications. The germination capacity of all strains

was 80%. Sowing rates of 2 and 5 kg/ha (row width 36 cm) and of 10, 30 and 60 kg/ha (row width was

18 cm) were tested. Weed control was only necessary at 2 and 5 kg/ha and was carried out by hand. Harvest took

place at seed maturity, when about 75% of the seeds of the whole population were matured. After drying, the

inflorescences were separated from the stalks by hand.

Greenhouse experiment-

The cultivar, 'Kompolti', was grown in pots within two identical glasshouse

chambers between August 4 and November 20, 1997. Plants were fertilized with Wuxal®. Thrips, present at the very

beginning of the experiment, were controlled with Cymbush®.

About four weeks after sowing, the light was reduced from 18 to 12 hours to

initiate flowering. Male plants were removed in both chambers to avoid

uncontrolled pollination. Three weeks after the day length change, pollination was

accomplished in one chamber by the daily shaking of mature male plants. Two months

later, when the seeds had matured (75-100%), the plants were harvested.

Distillation took place in a copper pot

with 1 liter tap water added. The amount of plant material was 350-450g fresh weight,

containing mainly inflorescences and some leaves, but no stalks. Plant material was separated by hand

and came from the upper 50 cm of the plant. Condensation was done by simple water cooling. Essential oil was

collected using a separating funnel.

Chemical analysis were performed by GC

(Supelcowax 10 column) and GC/MS in the Central Laboratory in Biel, Switzerland.

The quality of an essential oil cannot be determined

in empirical terms. Essential oil is composed of hundreds of substances from which only a small percentage are yet

identified. It is not known which compound or mixture of compounds is responsible for a "good" or a "bad" scent.

We can only evaluate whether it smells better or worse than other ones.

Scent tests were carried out by two essential oils

specialists (A. and L. Mächler, Essencia AG, CH-8400 Winterthur). The oils of the harvest time experiment were

compared within strains to generate an ordinal ranking list for each strain depending on the harvest time. Greenhouse

experiment derived oils were compared in pairs of one oil sample from pollinated and one sample from non-pollinated

plants.

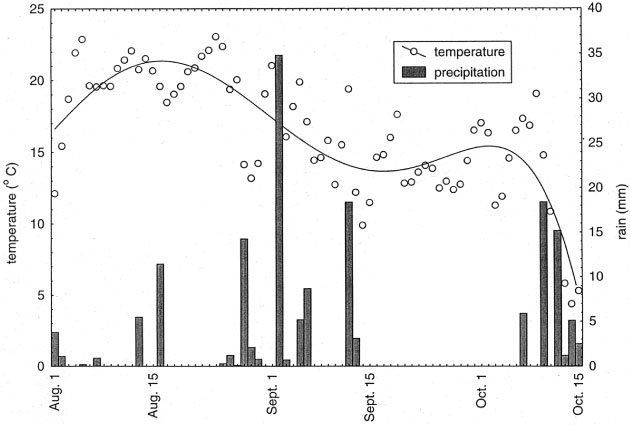

Mean daily temperature and precipitation of the trial location during harvest time.Figure 1.

Results

Field experiments-

The precipitation during late summer and autumn

1997 was unusually low (Figure 1). August and September were comparatively dry with 41.8 and 70.9 mm rain per

month. The temperature was in the mean range.

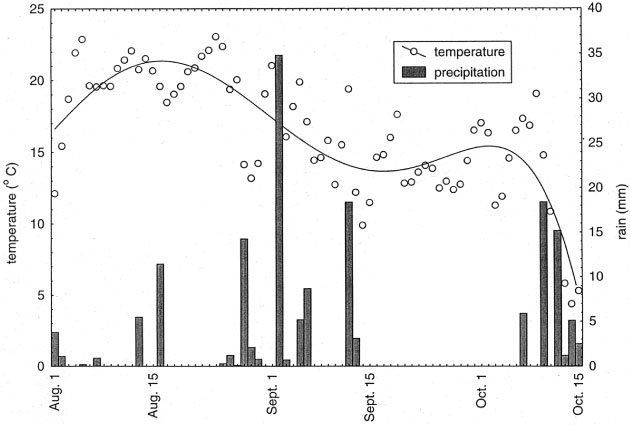

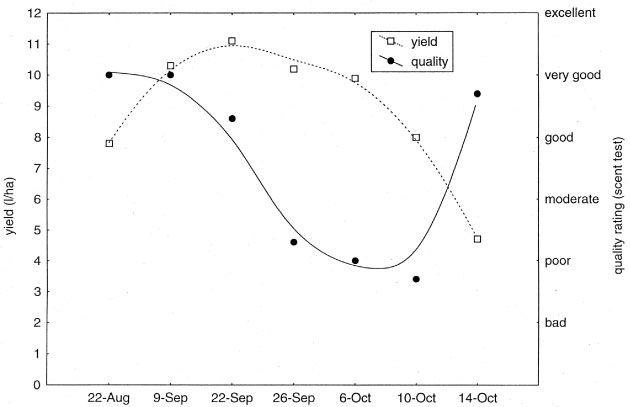

Essential oil yield of hemp depending on harvest time.Figure 2.

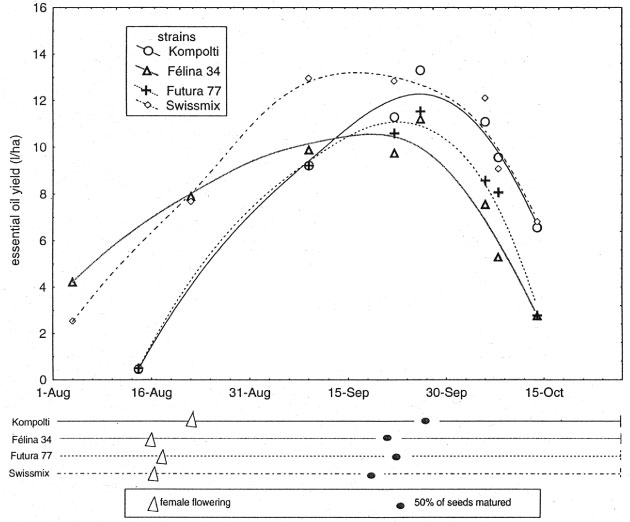

Quality of the essential oil hemp depending on the harvest date.Figure 3.

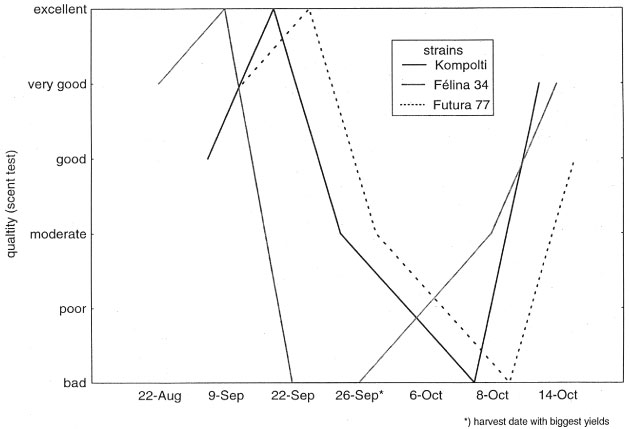

Figure 4. Yield and quality rating of hemp essential oil (mean yield values of 'Kompolti', 'Félina 34', 'Futura 77' and Swissmix and mean quality ratings of 'Kompolti', 'Félina 34' and 'Futura 77').

Harvest time experiment-

Figure 2 shows the amount of essential oils in

relation to the harvest time, expressed in l/ha. Yields of all four strains more or less continuously increased up to a

maximum value at the stage when about 50% of the seeds had reached maturity. In October, during senescence, the

yields decreased.

The pattern of essential oil quality,

depending on the harvest time, was different. In our classification, the best quality of the strains

‘Kompolti’, ‘Futura 77’ and ‘Félina 34’ was always obtained before the highest yields were

reached (Figure 3). In the case of ‘Kompolti’ and ‘Futura 77’, quality was highest 4 days earlier

than the maximum yield was reached. The best quality of essential oil from the strain ‘Félina 34’

was gained 17 days before the highest quantity. At the stage of the highest yield, the quality was

only moderate (for ‘Kompolti’ and ‘Futura 77’) or even bad (‘Félina 34’).

The results of the chemical analysis showed no significant relationship between any

detected compound and the relative quality marks or the harvest dates.

Table 2 gives an example of the chemical

composition of the essential oil of the strain 'Kompolti' depending on the harvest date.

Figure 4 summarizes the course of the

mean values of yield and quality of all strains in time.

|

|

|

|

|

| α-Pinene | 15.6 | 14.3 | 20.0 | 13.3 | 14.2 | 19.4 |

| β-Pinene | 6.2 | 6.0 | 7.5 | 5.6 | 5.6 | 7.2 |

| Myrcene | 21.2 | 30.9 | 28.5 | 36.2 | 35.6 | 31.1 |

| Limonene | 3.7 | 3.7 | 4.7 | 4.5 | 3.6 | 4.4 |

| β-Phelandrene | tr | 1.5 | tr | 1.4 | 1.4 | tr |

| trans-Ocimene | 3.5 | 6.7 | tr | 5.2 | 6.0 | 2.1 |

| α-Terpinolene | 3.5 | 9.1 | tr | 8.8 | 8.7 | 1.6 |

| trans-Caryophyllene | 25.5 | 16.5 | 10.6 | 14.6 | 15.0 | 15.7 |

| α-Humulene | 7.4 | 5.0 | 4.9 | 5.1 | 5.2 | 5.8 |

| β-Farnesene | 1.7 | 0.9 | tr | tr | tr | tr |

| α-Bergamotene | 1.5 | 1.0 | 1.4 | 0.9 | 0.8 | 0.9 |

| Caryophylenoxide | 4.3 | 2.0 | 11.5 | 2.1 | 3.2 | 5.8 |

| total monoterpenes | 53.8 | 72.1 | 60.7 | 74.9 | 74.9 | 65.7 |

| total sesquiterpenes | 40.3 | 25.4 | 28.4 | 22.6 | 24.2 | 28.1 |

| quality (scent test) | good | excellent | moderate | poor | bad | very good |

| tr = traces of the compound were detected but not quantified |

Sowing density experiment-

In all three tested strains, the sowing

density of 5 kg/ha led to significant higher inflorescence yields compared with sowing

densities of 2, 10, 30 and 60 kg/ha (Figure 5). At harvest time, the sowing density of 5 kg/ha

showed a plant density of about 15 plants per square meter.

Figure 5. Inflorescence yields of hemp depending on seed density.

Greenhouse experiment-

The yields of essential oils gained from

non-pollinated plants were more than twice as high as those pollinated (Table 3). The scent

tests did not result in a significant difference between the two different oil types. On an

ordinal ranking scale from bad to excellent, all tested oils from ‘Kompolti’ were rated "very

good" or even "excellent". The scent of oils from

non-pollinated plants was judged as being more intensive and more powerful. The scent originating from pollinated

plants seemed to be more of a typical "hemp odor".

Discussion

Essential hemp oil is thought to be synthesized at the same location as the cannabinoids, that is in the

epidermal glands or glandular hairs (Malingré et al. 1975). The highest density of glandular hairs is found on the bract

surrounding each female flower and the subtending leaflets of the female inflorescence (Hemphill et al. 1980,

Pate 1994). Thus, the essential oil yield can be maximized by increasing the amount of female flowers per area.

Strain-

Using monoecious varieties, it was possible to

increase the inflorescence yields (Figure 5). However, the essential oil yield of dioecious varieties was equal to or

higher than monoecious varieties (Figure 2). Differences between scent scores of

essential oil of different cultivars have been reported (Mediavilla and Steinemann

1997). Investigating the wide variability of

Cannabis sativa L. terpenoid phenotypes may lead to the discovery of new odors

which might be of interest for the perfume industry.

Plant density-

Maximizing the inflorescence yield can be done by optimizing the plant

density. In our experiment, the inflorescence yield was highest at the sowing rate of 5 kg/ha or about 15 plants

per square meter (Figure 5). At this plant density, weeds were not sufficiently suppressed by the crop. We presently

assume that the ideal plant density for highest essential oil yield to be the same

density as for highest inflorescence yield.

Harvest time-

It is clear that the abundance of glandular hairs

depends on the developmental stage of the individual female flowers, the inflorescence, the plant and the whole

population. The optimal harvest time for highest yield may be when the abundance of intact functional glandular hairs

is greatest. This is not a calendar date, but an ontogenetic time depending on the strain. Highest yield of essential oils

was gained when about 50% of the seeds had reached maturity.

The ideal harvest time for best quality (scent scores)

was somewhere between female flowering and seed maturity (Figure 4). Depending on the strain, this may be

quite a long period. For the strains ‘Kompolti’ and ‘Futura 77’, best quality was found about one week before seed

maturity (75% mature seeds), for the strain ‘Félina 34’ about three weeks before. It seems that the harvest time for

best quality has to be determined for each strain. The increase of quality during maturation is astonishing and

presently cannot be explained. Compositions and amounts of the detected substances by chemical analyses did neither

correspond to the quality marks of the scent tests nor to harvest dates. Thus, smell quality can still not be defined

by chemical composition.

Unfortunately, yield and the quality are never

highest simultaneously, and the time interval when both yield and quality are high is rather small (Figure 4).

Therefore, the optimal harvest time depends on whether the farmer (or the customer) is more interested in yield or

quality.

Prevention of pollination-

The female hemp flowers are thought to be fertile

only during a rather short time. Hemp is known to build large amounts of new flowers as long as it does not

become pollinated. Prevention of pollination leads to greater amounts of flowers and also to significant higher

essential oil yields (Table 3). This strategy is also known by growers of drug Cannabis and is called the

"sinsemilla" technique. Prevention of pollination in fields with a size of economical relevance is

nearly impossible, but easy to carry out in a greenhouse.

The quality of oils was rated as "very good"

or even "excellent", regardless if pollination took place or not.

| growing condition | mean yield (I/ha) |

| pollinated plants | 8.3 |

| non pollinated plants | 18.4 |

| LSD0.05 | 2.7 |

Climatic conditions-

As previously mentioned, the weather

during the 1997 period between female flowering and seed maturity was dry. There is evidence

for increasing resin production, glandular trichome density and cannabinoid content for

plants grown in areas with a lower humidity (Pate 1994). The same should be true for the

production of essential oil. In addition it is imaginable that a hard rainfall could destroy

glandular trichomes and thus decrease the yield of essential oil. The relatively low yields of the two last harvesting

dates (Figure 2) could be due to rainfall (Figure 1). In seasons with more rain, the yields are expected to be

smaller.

Other constraints-

The daily time of the harvest is said to strongly

influence the yield of essential oil. For example, it is recommended to harvest clary sage (Salvia sclarea) at

daybreak. Lavender (Lavandula sp.) and French basil

(Ocimum basilicum) should be harvested on bright sunny days (Husain 1994). In the case of hemp, it is not yet clear

whether the time of day of the harvest influences the yield. We harvested early in the afternoon on bright sunny days.

The quality of the water and the materials used in

the construction of the distillation equipment may have a strong impact on the quality of the oil (Mächler 1997). The

same is true for the harvest technique. Best quality is gained when only flowers harvested by hand are used for

distillation. Harvest by machine, whereby the whole plants (flowers and stems) are chopped, lead to lower quality

(unpublished data). Although hemp stems have a typical smell, it was not possible to gain essential oil from them.

Conclusions

Many factors influence both the yield and the quality of essential hemp oil.

Selection of the strain is important. Within the broad

range of varieties there is also a broad range of different smells. The tested strains ‘Kompolti’, ‘Félina 34’ and

‘Futura 77’ smelled quite pleasant and yielded appropriate amounts, but there might be many other varieties leading to

similar or even better results.

Under our conditions, we recommend a seed

density of 5 kg/ha. At this rate, yield is highest, but it is not clear whether quality is influenced. The prevention of

pollination would be another approach to increase the yield. However it is nearly impossible to carry out in the

field.

The weather is expected to have a major impact, at

least on the yield. A fairly dry period between the beginning of female flowering and seed maturity is

desired.

A very important point to heed is the harvest time.

For a maximal yield, the flowers should be harvested when about 50% of the seeds are matured, shortly before

seed maturity (75% matured seeds). To gain an optimal scent quality, it is recommended to harvest between three

days to three weeks earlier, depending on the strain. The daily harvest time may also influence the yield and the

quality, but has yet to be tested.

Harvesting of the flowers and separating them from

the stems by hand results in a very good scent. Harvest by machine is faster, but the distillation of both chopped

flowers and stems decreases the oil quality.

Distillation equipment and water is said to have an

impact on the quality, too.

The influence of these factors on yield and quality

of hemp essential oil is summarized in Table 4.

| factor | yield | quality |

|---|

| cultivar | + | + |

| sowing density | + | ? |

| pollination | + | + |

| weather | (?) | (?) |

| ontogenetic harvest time | + | + |

| daily harvest time | ? | ? |

| harvest technique | ? | + |

| distillation equipment | ? | + |

| distillation water | ? | + |

| + = positive effect | |

| - = no influence | |

| ? = not yet known | |

| (?) = not yet known but influence highly expected |

References

Acknowledgments

We thank S. Guarneri, T. Probst and F. Gmunder for their

help collecting plant material, I. Slacanin for the chemical analysis and A. and L. Mächler for the scent tests. This work was

supported by the Fachverein für Arbeit und Umwelt, the cantons BL, BS, SO and AG, the BIGA and the ITADA (Colmar).